What are the ‘must see’ Bauma products?

26 September 2022

The pandemic delayed the world’s largest construction equipment tradeshow, leading to pent up demand for new products and services. The Bauma tradeshow in Munich, Germany, October 24-30, is shaping up to be a haven for new product debuts in every sector, especially in lifting, rigging and specialized transport.

Bauma 2022 is shaping up to be a huge event for new product roll outs.

Bauma 2022 is shaping up to be a huge event for new product roll outs.

Bauma will be different this year because several companies made the decision not to exhibit. We are told the main reason for this was because Bauma is within six months of ConExpo, which will be held in Las Vegas in March 2023. Two huge tradeshows in six months were too much for some companies to handle budget and logistics wise. This scheduling problem will affect ConExpo as well. Regardless, Bauma and ConExpo will be great shows. The lead up to Bauma is as exciting as ever.

American Cranes & Transport and our parent company, KHL Group, will travel to Germany to cover Bauma just like we always have. Our Bauma Preview this month centers on what we have determined to be “must see” products and services for our North American readers, whether they make the trek to Germany or stay at home.

CRANES

Jekko Cranes is unveiling its flagship model, the electric SPX328. With a width of less than 31 inches (80 centimeters), this mini crawler crane can drive through standard doorways. The crane weighs 2,300 kilograms and has a maximum load capacity of 2,800 kilograms, a maximum height of 10.5 meters and a reach as long as 8 meters vertically and 8.5 meters horizontally. The machine is 2.95 meters long and 1.61 meters tall.

Powered by lithium-ion batteries, Jekko said the crane is easy to configure and operate with its radio control and its interactive display featuring a user interface that is new to the minicrane sector. This Graphic User Interface (GUI) configures the crane parameters on a 10-inch touchscreen featuring an IP67 Protection Rating for operation no matter what weather conditions.

The Jekko SPX328 features its tools onboard, including outrigger mats, hook, single-line hook block, four-lines hook block and runner jib.

The largest exhibitor at Bauma, Liebherr will show off its latest product development innovations in construction equipment, cranes, material handling, mining and components. The Liebherr stand will feature more than 14,000 square meters of space with some 70 exhibits.

The LR 12500-1.0 with a 2,500-tonne load-bearing capacity supplements the portfolio below the LR 13000.

The LR 12500-1.0 with a 2,500-tonne load-bearing capacity supplements the portfolio below the LR 13000.

With the slogan “Game changer for tomorrow’s energy,” Liebherr presents a new crawler, the LR 12500-1.0 with 2,500-tonne load-bearing capacity. This crane supplements the portfolio below the LR 13000. The designs of the rotating platforms and the main boom set new standards because the wide main boom gives the crane the stability of a power boom, Liebherr said.

“The new LTM 1110-5.2 combines old strengths with future-oriented innovations for greater safety and comfort,” Liebherr said. With this crane, Liebherr produces a completely new crane design in this series.

Other crawlers include the LR 1130.1 unplugged and LR 1160.1 unplugged from Liebherr in Nenzing.

For the first time on a global stage, Link-Belt Cranes will present its latest rough terrain crane, the 85-ton 85|RT. The crane made its debut in North America last fall at Link-Belt’s CraneFest 2021.

“General contractors and fleet owners will appreciate the competitive chart and value this crane delivers, not to mention it transports under 105,000 pounds with full counterweight and under 86,000 pounds with no counterweight,” said Brian Elkins, Link-Belt’s RT product manager. “This 85-ton (85|RT) was the next logical choice and really an easy decision for introduction following the 120|RT and 100|RT design.”

Link-Belt’s cab design for its rough terrain cranes has been well received in the field. Cameras on the 85|RT include heated rear-view, right side swing and winch cameras.

Link-Belt’s cab design for its rough terrain cranes has been well received in the field. Cameras on the 85|RT include heated rear-view, right side swing and winch cameras.

A six-speed transmission on the 85|RT is powered by a Cummins Tier 4F QSB 6.7 270 hp (201 kW) diesel engine. The 85|RT includes new drive train and counterweight removal systems. The 85|RT comes with a full power, five-section formed boom 38 to 142-foot built to Link-Belt’s specific boom profile and tolerances.

An available two-piece Link-Belt patented SmartFly, 35 to 58 feet, provides greater flexibility and range, and manually offsets at 0, 15, 30 and 45 degrees, the company said. Link-Belt’s Variable Confined Area Lifting Capacities (V-CALC) system features virtually infinite outrigger configurations with real-time 360-degree charts.

Manitowoc Cranes has designated Bauma as its global stage for new products this year and will launch its latest AT, the Grove GMK6400-1. Following in the footsteps of its popular predecessor, the new crane retains the much-loved features of the original and adds notable new technologies for a stronger overall offering, according to Andreas Cremer, Manitowoc’s vice president of product management for ATs.

Maximum tip height for the Grove GMK6400-1 is 136 meters when fitted with its full complement of jib.

Maximum tip height for the Grove GMK6400-1 is 136 meters when fitted with its full complement of jib.

Like the GMK6400, the new GMK6400-1 has a maximum capacity of 400 tons and a main boom of 60 meters. Manitowoc has packed the GMK6400-1 with new innovations, including an improved hydraulic system with faster flow to provide quicker operating speeds and even smoother movement. Also added to the new 400-ton machine is the Crane Control System (CCS) and MAXbase variable outrigger positioning system.

The new engine on the GMK6400-1 conforms to the latest requirements for both Tier 4 Final Emissions Standards and EUROMOT 5. As with the original GMK6400, the new GMK6400-1 includes the optional capacity-enhancing MegaWingLift.

Ormig has expanded its indoor range of electric cranes with the debut at Bauma of the 15iE, 35iE and 100iE.

These cranes cover lifting capacities from 15 to 100 tons with the versatility of modular counterweights and small dimensions, the perfect combination to facilitate the transport of the cranes on truck trailer, the company said. Among the attributes of the “iE” models is the minimum steering radius with an Ormig-patented steering axis the cranes can rotate on themselves, always keeping four contact points on the ground to guarantee the best lateral stability when moving with a load applied.

Ormig cranes feature remote control for all movements, fly-jibs that can be mechanical or hydraulic, winch, forks and front-jacks.

Ormig cranes feature remote control for all movements, fly-jibs that can be mechanical or hydraulic, winch, forks and front-jacks.

The patent for the rear steering axis shows a kinematic mechanism that links the electronic steering with mechanical steering with the purpose to avoid sliding of the wheels on the ground and to optimize the accuracy and smoothness of the steering.

Palfinger’s Strategy 2030 is based on the pillars “Go for Solutions” and “Go Digital,” which go together with the end-to-end digitalization of all company sectors and product lines, according to CEO Andreas Klauser.

Palfinger will present an innovation that is a powerful example of harnessing the latest technologies, electrification and successful development cooperation - ZF eWorX. Palfinger developed eWorX in cooperation with ZF Friedrichshafen and Mercedes-Benz Trucks to make optimum use of all the advantages of the electric drive system. With this module, every Palfinger product can be set up and used on a high-voltage truck.

Palfinger’s eDRIVE offers three different variants of electrically operated cranes. The energy can be obtained directly from an integrated battery, by plugging in to an external power source or from an integrated generator.

Palfinger will show its new eDRIVE for the Palfinger PK 29.502 loader crane.

Palfinger will show its new eDRIVE for the Palfinger PK 29.502 loader crane.

Palfinger will also show its Smart Control, the intuitive crane tip control system for loader cranes and timber/recycling cranes. Palfinger’s Fleet Monitor platform supports fleet managers in their work with digital intelligence, while the Operator Monitor app does the same for truck drivers and crane operators.

Tadano’s motto for Bauma 2022 is “Your Passion. Our DNA.”

“We’ll be taking advantage of this year’s Bauma to show an international public everything we’ve achieved in the past few years and the enormous progress we’ve made in a number of areas that benefit our customers,” said Tadano Faun and Tadano Demag CEO Jens Ennen. “For our customers, cranes are more than just another tool that they use. We share their passion for cranes. Our employees often say that cranes run in their blood – they are part of our DNA. For us, every single lift that is performed is just as important as it is to the customer.”

Tadano’s stand will show the first cranes jointly developed by Tadano’s Lauf and Zweibrücken locations in Germany.

Tadano’s stand will show the first cranes jointly developed by Tadano’s Lauf and Zweibrücken locations in Germany.

The starting point for the OneTadano strategy was the integration of Demag into the Tadano Group in 2019, with the goal of becoming Number 1 worldwide in the lifting equipment industry. A major initiative in that strategy was the recent launch of the Tadano AC 2.040-1 all-terrain crane, which is the first all-terrain crane jointly developed by Tadano’s Lauf and Zweibrücken locations in Germany. The AC 2.040-1 is the very first member of the future Tadano AC family that will share the same DNA with: a standardized crane control system, cab, on board diagnostics, telematics and many other technologies.

Tadano has launched 12 new cranes and solutions on the market since 2019. The list includes the AC 2.040-1, AC 4.070L-1, AC 4.080-1, AC 5.120 1, AC 7.450-1, HK 4.050-1 and HK 4.070-1 models, as well as a telescopic boom crawler crane that is produced in Zweibrücken, the GTC-2000. Plus, three GRT rough terrain models were launched.

At Bauma, visitors can also try out a number of Tadano tools, including the LiftPlan outrigger load and work range tool, IC-1 Remote & Hello Net and the new Heavy Goods logistics planning tool.

TOWER CRANES

Spanish tower crane manufacturer Comansa will showcase the brand new LCH300 hydraulic luffing jib crane among other new products. The launch of the LCH300, Comansa’s first hydraulic model, has a maximum load capacity of 16 tonnes and reach of 60 meters. The LCH300/16 t is available in various versions: embedded, supported on bases of 6 or 8 meters or movable. The crane can be assembled with 2.5- by 2.5-meter tower sections. Its modular jib has a reach of 25 to 60 meters, with configurations every 5 meters. It has a minimum working radius of 4 meters and a minimum radius of 9 meters when out of service.

The Comansa LCH300 incorporates the award-winning CUBE Cab. The cabin platform can be ransported in a single piece.

The Comansa LCH300 incorporates the award-winning CUBE Cab. The cabin platform can be ransported in a single piece.

The crane has manual transmission combinations of 1T (direct pulling) and 2T. The maximum load capacity is 8 tons with the 1T configuration and 16t with the 2T configuration. The maximum load at the jib end is 3,400 and 3,150 kilograms, respectively.

From the cabin there is direct visibility of the lifting mechanism between 50kW (standard) and 65kW (optional). Due to the Effi-Plus technology, it is possible to increase the speed of the lifting mechanism without affecting consumption, which allows loading cycles to be considerably reduced.

Jaso is launching two new models. The flat top J235.12 is a higher version of Jaso’s flat top J200.12 model. It features a maximum load of 12 tons and a tip load of 2.6 tons at 65 meters. It has a boom length of 30 to 65 meters in 5-meter by 5-meter increments. It has a short swing radius and 14.9 meter lay flat counterweights. The maximum free standing height is 55.9 meters with the 1.75 meter tower system.

Jaso will launch two models, the flat top J235.12 and the Low Top J390.

Jaso will launch two models, the flat top J235.12 and the Low Top J390.

Jaso will also show the first impression of the new Low Top J390, which Jaso said fills in the space of the 400-ton-meter range. This crane has a maximum load of 24 tons, a tip load of 3.8 tons at 75 meters and boom lengths in 5-meter increments. The crane has been optimized for transport and smart assembly.

Jaso will also show the upgraded version of the JL25 crane drivers lift which offers ultimate safety with two redundant drives.

Liebherr extends its line of Fibre tower cranes with its luffing jib crane 258 HC-L 10/18 Fibre, the high-top crane 1188 EC-H 40 Fibre, as well as the flat-top cranes 520 EC-B 20 Fibre and 370 EC-B 16 Fibre. Cranes with high-strength Fibre ropes offer even greater performance, which is particularly noticeable in large cranes. With the 195 HC-LH 6/12 Liebherr showcases its first hydraulic luffing jib crane in combination with a slim and climbing tower system. Liebherr is also working on future-oriented solutions in order to make crane driving even safer and more efficient. An excellent example is the tele-operation for tower cranes, which allows the machine to be controlled outside the crane cab.

Italian heritage crane manufacturer Raimondi Cranes is set to showcase a variety of new machines alongside a new accessory. Raimondi’s senior leadership team, together with its full official agent roster, will welcome visitors onsite for the entire duration of the event.

“We are extremely excited to showcase our new range of products,” said Cristian Badin, commercial director of Raimondi Cranes. “This edition of Bauma will also be our opportunity to present the Raimondi of the future; over the past year we have been working to reinvigorate both our core values and mission, as well as our product line. We’re very much looking forward to welcoming our clients, industry colleagues and guests at this year’s event.”

With its motto, “Wolffkran is Family,” the tower crane manufacturer is presenting a new concept: the WOLFF FX 21 Clear crane family. It will be joined by the WOLFF 8076 Compact, Wolffkran’s first trolley jib crane in the 800 metric ton capacity. Also new at the stand will be the WOLFF 235 B luffing jib crane and two new WOLFF tower sections: the 6-meter TV 60 and the reinforced 1.5-meter TV 15.

The WOLFF FX 21 Clear family.

The WOLFF FX 21 Clear family.

The WOLFF FX 7021 is the largest model of the new WOLFF FX 21 Clear family. The new family concept provides total flexibility in switching between three flat-top models in the 141-200 mt class: The WOLFF FX 6021 Clear, FX 6521 Clear and FX 7021 Clear. All three models have a tip load capacity of 2.1 tonnes.

The patent-pending WOLFF High-Speed Positioning System, which virtually eliminates load sway, will also be demonstrated. Wolffkran is the first manufacturer in the industry to develop and launch such an assistance system, significantly increasing safety and work efficiency on construction sites, the company said.

TRAILERS & TRANSPORT

Goldhofer has been a pioneer in the field of wind turbine blade haulers since 2013 with the FTV 300. Today more than 60 units in different versions are in successful operation around the world. Since then, wind turbine blades have grown longer and heavier and the Goldhofer FTV has grown with them.

Among the many transport solutions Goldhofer will show in Munich will be the new FTV 850 together with a variable width PST/SL-E ½ + ½ split combination. Due to the individually adjustable widening of the vehicle and hydraulic support circles, the combination achieves improved lateral stability and enables the transport of loads with a high center of gravity. At the same time, a smaller number of axle lines is required for transport and noticeable fuel savings are made possible.

Scheuerle will show its expanded SPMT PowerHoss series with the addition of a six-axle version featuring a width of 3,000 millimeters. These transport modules now offer up to 330 metric tons of payload per unit and can also be used in a vehicle combination.

The SBL600 telescopic hydraulic gantry from Enerpac will be a focus at the company’s Bauma stand.

The SBL600 telescopic hydraulic gantry from Enerpac will be a focus at the company’s Bauma stand.

Scheuerle has always offered SPMT PowerHoss modules with two and four axles; however, a version with six axles now complements the series. While the two and four-axle versions offer payloads of up to 85 and 174.9 metric tons per module respectively, the six-axle vehicle accommodates up to 330 metric tons of payload. In addition, individual Scheuerle SPMT PowerHoss modules can be operated according to the plug-and-play principle either mechanically or electronically in a loose coupling mode as well as being coupled to one another both laterally or longitudinally in order to meet even higher payload requirements. Thus, a vehicle combination of four SPMT PowerHoss 330s is able to move loads with a unit weight of up to 1,320 metric tons.

RIGGING GEAR

The centerpiece of the Enerpac stand will be the new SBL600 telescopic hydraulic gantry, along with the company’s entry-level gantry system for industrial movers, the ML40 Mini Lift Gantry. The new E-mover battery-powered load skate will also be demonstrated together with the SCJ-Series 50T Cube Jacks-Ups. The stand will also feature the growing range of Enerpac industrial tools and cylinders now available for heavy lift as well as construction and maintenance projects.

The booth will also feature a JS-250 Jack-Up, strand jacks, a multi-point lifting EVO system and low height skidding systems and trolley systems to facilitate the movement of loads. The ETT-Series turntable capable of handling loads up to 400 tons will be demonstrated.

The SBL600 Super Boom Lift hydraulic gantry is a three-stage telescopic hydraulic cylinder with rectangular boom for increased capacity and first stage lifting capacity of 674 tons and 416 tons at the third stage.

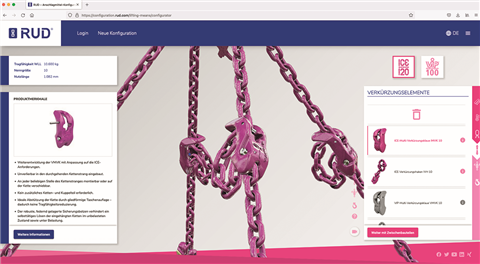

German supplier of sling and lashing technology RUD will present its new service, the sling configurator. With a 3D view, chain slings can be configured online quickly and safely. During every configuration step, the web application provides background information and practical hints on lifting and moving loads as well as on RUD products. Rud will show several tools from its rigging gear product line.

At The Crosby Group stand, look for the offshore galvanized BKLK self-locking hook. The Crosby team developed this hook as a game-changer in durability. They are also third-party type approved by DNV to relevant offshore standards.

The Crosby Group will showcase a variety of hooks, including the BKLK self-locking hook.

The Crosby Group will showcase a variety of hooks, including the BKLK self-locking hook.

In the early 1960s, Karl-Axel Wahlström and Stig Lindgren were credited for the first prototype of the BK hook, an abbreviation of ‘Byggnadskrok’, which in Swedish is a combination of the word byggnads, meaning construction, and krok, meaning hook. The product was patented and released to the market in 1965. The BK and Crosby Shur-Loc hooks produced by The Crosby Group today are very similar, and both are now designed to avoid fingers getting pinched when opening the hook, which is a common problem with lower quality hooks.

The Crosby Group offers clevis self-locking hooks that connect directly to a chain sling; ball-bearing swivel hooks that can rotate under load; a Griplatch hook with a latch that connects to the body for improved side-stability and reduced weight; galvanized hooks for severe-weather protection; and even a special self-locking version for skip-loaders.

Crosby will also show its Block Cam camera line and other technologies.

SAFETY TECHNOLOGIES

AMCS specializes in anti-collision safety systems for lifting equipment. Its latest innovation includes the DCS 61-S (Driving Control System Safety) anti-collision and zoning device, designed as an evolving product to integrate new requirements as they arise. Certified PLd in accordance with the standard EN13849-1 and SIL-2 in accordance with the standard EN61508, the DCS 61-S is now managing interferences between tower and mobile cranes. The DCS 61-S automatically detects the movements of mobile machinery and integrates the servo-control of tower cranes.

Through its Vortex Studio platform, CM Labs provides capabilities for training simulators, mission rehearsal, virtual prototyping and testing.

Through its Vortex Studio platform, CM Labs provides capabilities for training simulators, mission rehearsal, virtual prototyping and testing.

The DCS 61-S calculates in real time and in 3D the distances between each element of the cranes as well as the speeds of movement to intervene on the control mechanisms of the machine to ensure a slowing down, then a complete immobilization of the tower crane at a pre-set distance from the mobile machine. AMCS will also release a new video camera, the CAM 61.

Located in the Canadian Pavilion, CM Labs Simulations, developer of Vortex training simulators, will showcase its latest simulation training and assessment solutions. The new releases include training packs for compact track loader, telehandler and articulated dump truck, all running on the Vortex Advantage and the entry-level Vortex Edge Max. Both simulators will be deploying CM Labs’ full catalogue of earthmoving and lifting equipment, including the recent boom truck simulation training pack.

Safety controllers of the WIKA CTL-S700 series enable high-level safety for mobile machines. The controller offers many interfaces and I/Os for machine control tasks. A data logger collects relevant operating data. Multiple CANopen safety and Ethernet interfaces are available. The CTL-S700 series offers up to 64 inputs and 56 outputs, allowing the controller to network in the system.

MYCRANE, which will be showing the benefits of its crane rental platform, recently added four new types of lifting devices, including boom trucks, hydraulic gantry systems, mini cranes and aerial platforms. MYCRANE has pioneered a free-to-use, digital crane rental service, allowing users to post their lifting requirements free of charge online. Crane rental companies then respond directly with their commercial offers, eliminating the need for customers to make multiple offline requests. Other MYCRANE services include a free crane selector tool to help identify the right crane, advice for engineering, project management and support, and a marketplace where equipment, rigging equipment, spare parts, auxiliaries and industry vacancies can be posted.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.