Rope and winches: Bounds of possibility

20 April 2020

One of the biggest developments in the rope sector in recent times comes from a co-operative relationship between Austria-based rope manufacturer Teufelberger and Switzerland-headquartered crane manufacturer Liebherr. Together they developed Solite fibre rope which went into series production in 2019 along with Liebherr’s new Solite-equipped EC-B ‘Fibre’ flat top tower cranes (240 EC-B 10 Fibre / 240 EC-B 12 Fibre / 370 EC-B 12 Fibre).

Both companies believe Solite will prove to be a game-changer, especially for the tower crane sector, by enabling the current boundaries of possibility, particularly with tower crane applications, to be pushed. The companies also say Solite has multiple benefits for mobile crane and crawler crane applications.

According to Teufelberger, the safety and operational advantages Solite offers include an up to 80 per cent lower rope weight, the crane components do not wear, and the rope does not need to be lubricated. The rope’s point of discard is easy to determine, it adds, as it is indicated via the rope’s red core. When this can be seen the rope must be discarded, even though it still maintains 100 per cent of its breaking load at this point.

Teufelberger also says Solite’s life cycle is much longer than wire rope. Björn Ernst, R&D manager for Solite at Teufelberger says, “Solite can, compared to a steel cable, reach up to ten times the service time in multi-layer windings.”

“The fact that Solite could revolutionise a market that has been dominated by wire rope technology excites me,” adds Erich Rührnössl, one of the Teufelberger team behind the development of Solite.

Component choice

Tried and trusted technology is preference of tower crane manufacturer Moritsch Cranes when it comes to its choice of tower crane componentry and, in particular, its winch drums. Although the company is relatively new, being launched in 2015, it was founded by Mariano Moritsch who, along with his family, has a long history in the tower crane industry. The company’s range of luffing jib (RTL), flat-top (RTM) and low-top (RTT) cranes from 100 to 600 tonne/metres cranes can be found in cities around the world. All of the engineering is carried out in-house and Mariano prides himself on using high quality components. “I strongly believe that if we did not have top quality components we could not have had the success that we have had over the past three years,” he says. “It is very important that I can tell my customers we only use premium components.”

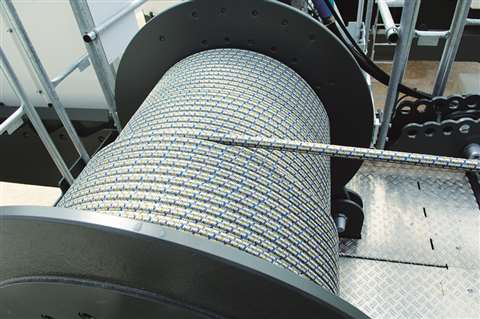

Moritsch’s winch drums come from Bavaria, Germany-headquartered company Lebus International Engineers. The Lebus system is well known in the lifting industry for ensuring wire rope spools continuously onto and off rope drums in multiple layers. The Lebus groove differs from a conventional helical (screw thread) groove in that the groove runs parallel to the flanges (edges) of the drum except for at two points on opposite sides of the drum where the groove is slightly angled, just enough to keep the rope moving along to the drum face. This geometry was designed and patented in the 1950s by Texas oilfield equipment supplier Frank LeBus. The design patent has long since expired and similar-style parallel grooved drums have become widespread. The Lebus brand, however, remains protected by Lebus Inc, the US parent company, and its subsidiaries in Germany and the UK.

“I tried a Lebus copy once but the performance was not the same,” Mariano says. “When we started Moritsch Cranes we decided to ensure that all of the drums should be Lebus, for their quality and reliability.”

Seeing the difference

Genuine Lebus engineering is especially important for the tallest cranes, Moritsch says. The more rope you need to spool onto and off the drum, the more scope there is for rope to get caught, damaged or twisted, bringing site operations to an expensive halt.

“If we have a crane that is 30 or 40 metres high, maybe you won’t see the difference,” Mariano says. “But with the highest cranes, especially the luffers, you see the difference.”

Thanks to Lebus, he says, the biggest Moritsch cranes carry up to 1100 metres of wire rope spooled in seven layers “and we have never had any problem”.

The drum that Lebus supplies is a key component of the overall winch system. Moritsch makes its own winches from supplied components. Components that are not tailor-made for Moritsch, such as the Brevini gearboxes and Stromag brakes, have characteristics that make them specifically suited to the application. The drums, however, cannot be purchased off the shelf and are all tailor made.

“We share technical information and find the solution together,” Mariano says. “Every product starts as a partnership.”

Communication is important because the size and shape of the winch drum is integral to the overall design of the crane, adds Lebus.

“When we start to manufacturer a new crane, the organisation of the spaces on the frame and counter jib is very important,” Mariano says. On larger Moritsch cranes, with more than 400 metres of rope, the winches are designed with the reduction gear inside of the drum, so this calls for even closer working with Lebus. “We study together the best technical solutions,” he says.

Lebus receives technical instruction from Moritsch, with full details of the rope to be spooled including its length, diameter, strength, type of construction and manufacturer. Lebus then designs a drum with specific grooving to match Moritsch’s criteria. The key for Lebus is determining the precise depth and width of the grooves that guide the rope spooling action so as to guarantee a lifetime of smooth spooling.

Every wire rope type behaves differently especially when spooled in multiple layers, says Lebus, and so needs different grooving geometry to get the best from it.

“We study the behaviour of wire ropes under working conditions for the given application,” says Cris Seidenather, who describes himself as “semi-retired” from the role as managing director of Lebus. Lebus simulates the winch application in its workshop in Finning, Bavaria, observing the impact on the rope and measuring how much the lower layers on the drum change shape under pressure from upper layers.

“Even if the wire rope construction is the same but comes from another manufacturer, the dimension behaviour can be different,” he says. “For example, the diameter reduction under tension might vary from manufacturer A to manufacturer B. That’s why in many cases it is important for us to know the name of the manufacturer.”

From this analysis, the drum design is produced.

“We finally send our complete drum drawing to Moritsch and he transfers the Lebus technical dimensional values in his drawings,” Seidenather continues. “Each time there is a new crane design and/or change in rope specification, rope manufacturer or construction it is our technical know-how to design the new groove and pitch dimensions.”

Different Moritsch crane models require different winch drum designs from Lebus, each custom-made for the application.

The hoisting winch of Moritsch’s RTL 265A luffing jib crane, for example, holds 900 metres of 22 mm diameter wire rope, spooled in seven layers and with a maximum rope pull of 110 kN. For this, Lebus supplies a drum width of 941 mm between the flanges and a pitch circle diameter of 922 mm. The optimum grooving pattern – the depth and width of each groove machined into the drum face – is Lebus’ special know-how.

For other crane models, the winch drum might be a different shape altogether. On the low-top RTT 470–24, for example, the drum has a smaller pitch circle diameter of 870mm but a longer face, with a length between the flanges of 1020 mm. This crane carries 850 metres of 20 mm-diameter wire rope spooled in six layers.

In every case, it is the geometry of the grooves on the drum face that keeps the rope behaving properly, assuring layer upon layer of perfect spooling, maximising rope life, up-time and return on investment.

“The quality of the drum is as important as the quality of the rope,” says Mariano Moritsch. “So we use only Lebus drums.”

In this way we can see the impact the choice of componentry has and the relationship between them, too, has upon the crane’s overall functionality.

In this way we see how the choice of components directly impacts the crane’s operating abilities. The interaction between the rope and winch drum, as outlined by Lebus, is evidently complex and it will be interesting to see how rope developments of the future integrate with the widespread use of traditional component technology.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.