Palfinger to build remote controlled offshore cranes

22 April 2022

Palfinger has been awarded a contract to build and further develop technology for remote controlled cranes by its client Norway-based Aker BP.

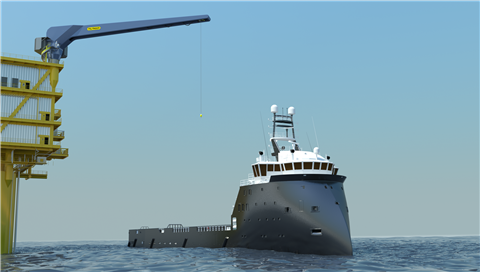

The ability to provide safe working conditions is one of the main drivers for remote and autonomous control, Palfinger said (Image: Palfinger)

The ability to provide safe working conditions is one of the main drivers for remote and autonomous control, Palfinger said (Image: Palfinger)

The Austrian manufacturer will equip Aker BP’s new installations with new offshore cranes that will be based on a new technology that aims to improve safety and reduce operating costs.

The agreement is valid for ten years with the option to extend. It covers the development and implementation of remote controlled cranes as well as the delivery of a total of six electric cranes for four platforms.

The oil exploration and development company, Aker BP, is planning a final investment decision in 2022 for the NOA Fulla field development in the NOAKA area (between Oseberg and Alvheim in the North Sea) and a new central platform on the North Sea Valhall complex.

Palfinger recently delivered four offshore cranes to the Valhall platform.

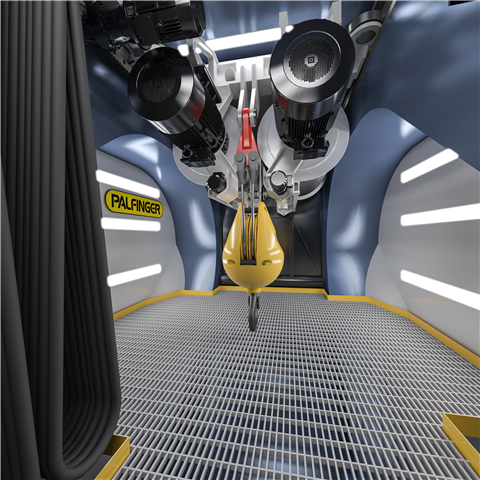

The crane contract covers developements over the next decade (Image: Palfinger)

The crane contract covers developements over the next decade (Image: Palfinger)

The ability to provide safe and secure working conditions is one of the main drivers for remote and autonomous control, Palfinger said.

The technology is also expected to offer cost savings, particularly for operations that traditionally require either calm weather conditions, large crews and facilities, or highly repetitive tasks that can be performed remotely with new digital tools.

Offshore partnership

In 2017, Palfinger started working on the concept for Remote Operated Offshore Cranes (ROOC) together with Aker BP and Optilift.

The technology of the ROOC for the new platforms will be based on the work done in the past years as well as the recent deliveries to the Valhall IP platform.

“NOA Fulla og NCP/King Lear are major field developments on the Norwegian Continental Shelf. The cranes Palfinger will deliver through the frame agreement represent a very important delivery in our operations strategy where remote work and automation are key drivers. By standardising cranes across these development projects, we can also improve quality and reduce costs,” said Ine Dove, SVP operations and asset development at Aker BP.

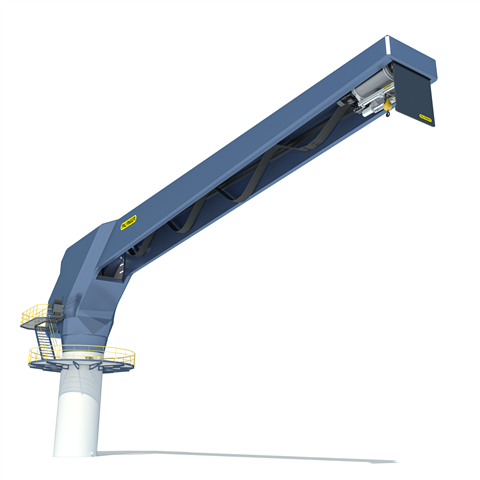

The new design will be remotely controlled (Image: Palfinger)

The new design will be remotely controlled (Image: Palfinger)

Andreas Hille, senior vice president product line management and engineering at Palfinger said, “We are excited to continue our cooperation with Aker BP on this project which combines innovation, research and development based on our many years of experience.

“Together we are setting new standards providing modular and scalable offshore cranes with integrated remote and autonomous control technologies.”

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.