Cox navigates rigging sector with acumen

03 May 2021

Christopher Cox is in it for the good – of his customers, his team and the industry.

Christopher Cox speaks about his work with inspiration and vision. As president of Engineered Rigging, he is hands on, genuine and intentional – whether engineering a complicated solution that involves fabricating custom equipment or developing a rigging plan using gantries and other rigging gear from their fleet.

After talking to him for just a few minutes, you can tell he is truly cut out for the work he is doing. He wishes everyone enjoyed their job as much as he does. He takes the stressful aspects in stride, appreciating the challenge of “thinking his way out of a problem.”

Did he ever envision running a rigging company? Not exactly, although he always had an acumen for engineering, construction and being in an industrial environment. A slow pace isn’t one that works for him.

“I’m wired pretty hot,” he admitted.

“I can’t just sit around.”

Christopher Cox, President, Engineered Rigging

Christopher Cox, President, Engineered Rigging

Shortly after earning his engineering degree, Cox worked as a design engineer for a company that produced pressure vessels. He then moved to the high-rise building realm, designing concrete and steel structures. With the economic picture for that sector bleak, he landed a job with Precision Surveillance Corporation, which performs post-tensioning on nuclear containment buildings. He relished being more hands on, rather than a “behind-the-desk” engineer. He worked his way up through the ranks at Precision, and by 2011 he was vice president, predominantly running the company from an operations perspective. Under his leadership, Precision grew exponentially.

“We were doing a lot of work on nuclear power plants and we had expanded our scope of work, doing more structural, moving and rigging type of work in addition to post-tensioning,” he said.

Around that time he met Eddy Kitchen, who had spent his career in the crane and rigging business and was eager to introduce Cox to the rigging sector.

Cox attended his first SC&RA event in 2013.

“That’s when I started talking seriously to Eddy,” Cox remembered. “Eddy and I were itching to start our own company.”

2017 spin off

Engineered Rigging was started in 2014 as a subsidiary of Precision. But that wasn’t enough for Cox. He negotiated an exit strategy that would allow him to spin off Engineered Rigging and take it to the next level. By January 2017, Engineered Rigging was an independent entity fully owned by Cox and Kitchen. It was a dream-come-true for both men, and with the combination of Kitchens’ equipment background and Cox’s engineering expertise, the company started growing and taking on challenging projects around the world. The company also became a distributor for Enerpac, selling and renting its unique brand of equipment.

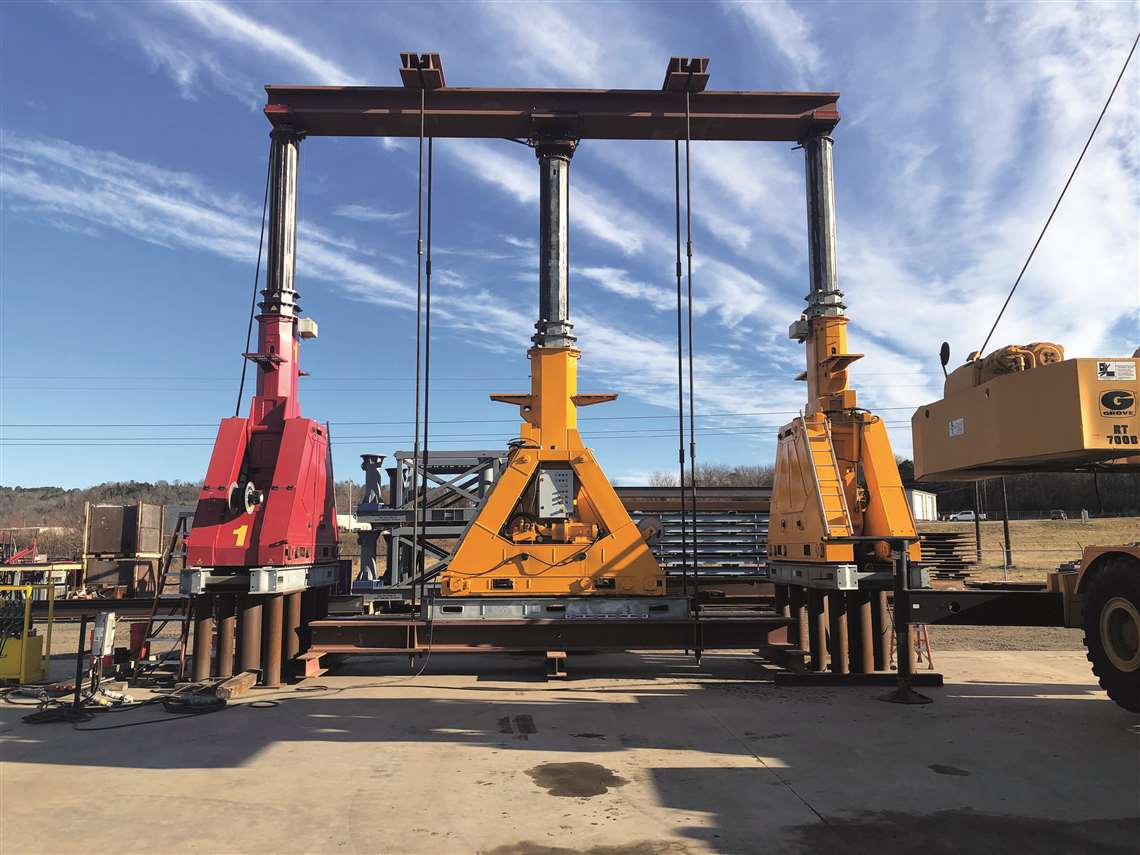

Engineered Rigging provides load testing at its Russellville, AR, facility. In 2021, ER provided a load test for an Enerpac SBL1100 gantry.

Engineered Rigging provides load testing at its Russellville, AR, facility. In 2021, ER provided a load test for an Enerpac SBL1100 gantry.

“We have accumulated a lot of gantries, strand jacks, skidding systems and other equipment and we have developed what we think is a different kind of entity,” said Cox. “Our specialty is creating solutions to help clients do what they need to do. This can involve engineering a solution, engineering and designing equipment or renting or selling equipment.”

Headquartered in Valparaiso, IN, Engineered Rigging operates a 17-acre fabrication and equipment facility in Russellville, AR, where they build the equipment they design and engineer, and where the equipment fleet is located. The company has offices in The Netherlands for European-based projects and in Chile for projects in South America.

What makes Cox tick?

“I’m always trying to think of a new way to make something better, safer, faster, and more economical,” he said. “Eddy and I look at things with different spectacles than most people. I love a challenge I can sink my teeth in. I can’t shut it off. Which can be a downfall of course because my brain doesn’t stop.”

Cox can think his way out of any challenge or problem.

“The thing that triggers my inspiration is for someone to say, ‘you can’t do that,’” he said. “As soon as someone says it can’t be done, I’m like ‘thanks for the challenge.’”

I met Cox at his first SC&RA meeting. Since then, we’ve reported on some of the jobs and projects Engineered Rigging has performed, including SC&RA Job of the Year projects.

Headquartered in Valparaiso, IN, the company operates a 17-acre fabrication and testing facility in Russellville, AR.

Headquartered in Valparaiso, IN, the company operates a 17-acre fabrication and testing facility in Russellville, AR.

Our interview was conducted while he was in the car, driving to his daughter’s soccer match. I was so impressed at how thoughtful he was while contemplating my questions. Cox is smart, enlightening and amusing. He is a positive force in the industry.

Engineered Rigging sells and distributes rigging equipment, and it offers turnkey rigging solutions. What type of equipment do you fabricate?

We’ve designed a lot of our own stuff. We come up with solutions our clients bring to us. Sometimes we use conventional rigging gear and other times the right thing to do is take your blinders off and be creative. Sometimes that means a custom piece of equipment. We will take your ideas and throw in some of our ideas, and it evolves. Then we figure out a way to manufacture what is required.

We developed 20-ton manipulator. It’s a combination between a scissor hoist and an engine hoist and a robot drives it around. It was designed particularly for picking up bonnets off of condensers. It was a result of someone having to remove a lot of structural steel. Our goal was to design a machine that could pick and flip and drive away with the load.

We designed a modular lift system that we can stack and use in different configurations. It can utilize hydraulic cylinders, strand jacks or actuators.

When we fabricate a piece of equipment, we try to add an element of modularity to it. We come up with smart pieces that we can reuse in other ways. Modularity allows for crossover. With a modular component in your toolbox, you can reuse and reconfigure with more pieces to create a new solution. But we don’t make something just to make it. Some folks do that. It needs to make sense to the solution.

What are the biggest challenges for Engineered Rigging?

The biggest challenges are having the correct resources with people who have similar mindsets to ours and to have the willingness to be creative and work hard at any level. There’s no job too small in our organization. And there’s no beating of our chests. It’s a team environment. We can’t live in silos. A lot of engineering groups do.

Some of the best ideas come from people who are not engineers. We want everyone to feed off this excitement. Having the right resources and the right people who want to do something really cool is a challenge. When we run across someone cut from the same cloth as us, we want them on our team.

Engineered Rigging provides custom fabrication, including lift columns, (pictured) for a client in the Midwest.

Engineered Rigging provides custom fabrication, including lift columns, (pictured) for a client in the Midwest.

What were the biggest obstacles navigating the Covid-19 pandemic?

The pandemic is very serious, and it affected so many things and so many people’s lives. We’ve been very fortunate. We have an office in The Netherlands and in South America. We are all separated. But we still had people out on projects. Some things got postponed, and delays were inevitable.

But for us, things have worked out okay. Last year was our biggest year since we started. We kept our people safe, and we kept everyone working. We followed all the proper protocols wherever we were. We had a project in Indonesia that was affected the most. We had to quarantine our team for 14 days. There were many details to work through everything contractually. We tried to buy local when we could and to help others who were hurting. We saw some very sad things.

On the lighter side, when I got home from Indonesia I was grounded. For more than 20 years I’ve travelled substantially. All the sudden I’m home all the time. My family was like, ‘Who is this guy? What is he doing here all the time?’

For a young person entering the industry, what is your best advice?

You need to approach it like a small child would approach it. Learn and learn and learn. Be willing to learn all types of things. Do not box yourself in.

There are so many really cool opportunities that incorporate technology, especially robotics. Young people need to get engaged in our industry. Learn what you can from being in the field and respect what needs to be done in the office. The more rounded you can be the better off you will be and the higher chances you have of being able to make a difference.

How does Engineered Rigging distinguish itself in the markets it serves?

The thing that is different is we like having personal relationships and offering a personal touch to our work. We treat people how we want to be treated. We treat our customers with kindness and respect, and we want to be fair and equitable. Most of our clients become our friends. We augment what they are doing.

It’s not just about generating business and increasing revenue. It’s about building relationships and trusting people. It’s fun to us. We like to have a good time.

Think about professional athletes. They are getting to do what they love to do. We do what we love too. That’s the kind of passion we put into our work.

As I’m driving to Indiana, we are going through this town with tons of windmills. My mind starts going through all the solutions we have for performing maintenance on windmills. We are always thinking about how we can develop new solutions.

What is your role in a project?

Typically, I play a role in the initial concept and developing the solution. And then we take that solution and get it knocked out.

My strength is coming up with the concept and having the vision of how we are going to do something. That’s where I get started and then things are passed around from there.

Sometimes I don’t get to do as much of this as I would like because I’m swamped with the operations side and also looking at opportunities to grow the business.

In the beginning, I did the project work from cradle to grave, but as we have grown and increased our team, I have to pass off more. I’m realizing that sometimes I don’t have enough bandwidth to do it all.

Can you name a project that sticks out in your memory as a favorite?

When I first previewed this question, I thought, each one is unique in itself. It’s hard to put my hand on one of them because all of these opportunities are so different – we do work in the nuclear space, material handling, packing and moving. We do work with the government, the Navy and NASA. Our projects are across many industries that are all unique.

But if I look back, there is one project that ended up looking really simple but involved a lot of complex engineering. It was an idea that allowed us to build everything, implement our solution and help the customer solve a problem. It was a conveyance solution. Initially, they wanted us to create a rolling platform across structural steel, from the floor to the ceiling. This would require a lot of scaffolding.

We asked if they were open to another idea. Our concept was taking a knuckle boom crane, building a chassis for it and placing it on a robot. There would be custom outriggers, and there would be the ability to lay track out over the open steel. There would be no need for scaffolding. You can fold the outriggers down and attach the crane to an existing structure. The idea evolved and we bought an OEM knuckle boom crane from the slewing ring up. From the slewing ring down, we designed everything. This kind of challenge is really fun. This solution worked well for them and for us.

The scaffolding solution meant more man hours, the risk of using scaffolding and working at height. In our business, our customers appreciate that we are always trying to mitigate risk.

But really, my favorite project is the last one. This work is very exciting.

What is your business philosophy?

That’s a tough one because it requires a big paint brush [to cover it all.] But really, it’s treating people how you want to be treated. I put a lot of faith in God with what I do, and I’ve been blessed. One of my big goals is to surround myself with people who want to make their lives better and do positive things in their communities. Another goal, and my wife and family are involved as well, is to help those who are less fortunate. We are active in the Catholic church and we work to help people. I think it’s important to try to give back.

Did you do anything beyond the norm during the Covid-19 lockdown? Bake bread? make jellies and jams?

Actually, there are a couple of things. A friend encouraged me to start running. I do it every day. We have been streaking and trying to get 365 days in a row. Today is 357 for me. A week from tomorrow I will have run every day for 365 days straight.

I have never been a runner. I never liked to run but when my friend (and colleague) challenged me, I decided to do it. He is 25 days ahead of me.

The other huge thing that is bigger than that, is that I’ve become closer to my Catholic faith. We joined a couple’s group that gets together every Sunday. This has changed a lot of my viewpoints because I brought my relationship closer to Jesus and to my Catholic faith. I’m trying to share that more, and I didn’t used to do that. These types of situations you really have the opportunity to increase your faith if you so choose and you can make your life so much better.

When I run, I listen to a couple of different podcasts that are faith based. I have to say I got tired of hearing all the negativity during the pandemic. I needed to listen to something inspiring and to try to be a better person.

What do you in your downtime?

Since we have three kids, ages 16, 14 and 11, and they all play soccer and club soccer, we spend a lot of time at the soccer fields. We love watching them play.

[While doing this interview, I’m with my daughter on my way to a tournament in Ohio.] It’s a chance to spend some one-on-one time with her. I know that I will blink, and they will be off to college. So, these are key moments I want to maximize.

I work a lot but when I have time I really like to be outdoors, hunting and camping. We don’t get to do it as much as we used to because our priorities have been rearranged. I also like riding a motorcycle. When I have free time, I will ride.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.