A new way of installing wind turbine components

22 May 2023

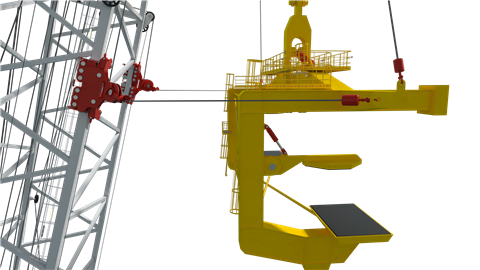

The Travelling Load Stabilising System was developed jointly by Huisman and Siemens Gamesa. Image: Huisman

The Travelling Load Stabilising System was developed jointly by Huisman and Siemens Gamesa. Image: Huisman

Stabilising wind turbine components during their installation is a major challenge for assembly crews.

Two companies in Europe have pooled their engineering resources and come up with a solution. Dutch crane and engineering specialist Huisman and Spanish wind energy specialist Siemens Gamesa worked together to produce the Travelling Load Stabilising System.

All components are affected but it especially applies to blades as they are designed to catch the wind. Controlling the movement of the relatively light components when suspended from a crane can now be done using the new system. It helps reduce downtime and increase the integrity of the delicate wind turbine components, Huisman said. It can be used on any heavy lift cranes.

The Huisman and Siemens Gamesa TLSS can be used with all heavy lift cranes for wind turbine component installation. Image: Huisman

The Huisman and Siemens Gamesa TLSS can be used with all heavy lift cranes for wind turbine component installation. Image: Huisman

How TLSS works

The system uses two pairs of tugger winches working together to control the position of the load. One pair is mounted on independent trolleys travelling along a rail on the crane boom. These trolleys follow the main hook block to maintain an optimal tugger line configuration, Huisman said.

The second pair operates from the tip of the crane giving a force perpendicular to the first pair of tuggers. This means by operating from different directions there is more control over the load than if using a conventional single pair of tuggers, Huisman explained.

There is a control system to hold the position of the load to give “a stiffer restraint, and therefore a higher position accuracy compared to conventional tugger systems that rely on constant tension,” Huisman said. If there is an overload the system gives way but returns to its set position after that overload force dissipates.

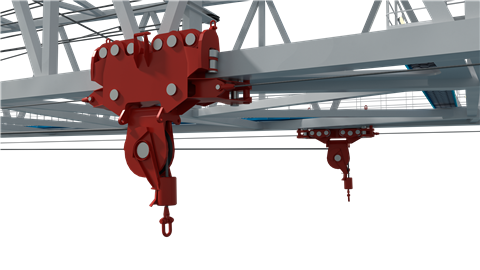

Close up of the system showing the trolleys (red) on rails fixed to the crane boom, and the yellow yoke of the blade carrier linked by wire ropes connected to winches. Image: Huisman

Close up of the system showing the trolleys (red) on rails fixed to the crane boom, and the yellow yoke of the blade carrier linked by wire ropes connected to winches. Image: Huisman

As an integral part of the crane the TLSS can be operated from the operator’s cabin or via a portable wireless controller.

Commenting on the new system David Roodenburg, Huisman CEO, said, “The only way to accelerate the energy transition is through innovation enabled by the joint forces of industry partners. We have done this by combining the operational knowledge and experience of Siemens Gamesa with the technical equipment knowledge of Huisman. With the Travelling Load Stabilising System, we are very proud that together we can offer installation companies an efficient solution to reduce weather downtime, a challenging and delaying factor of wind turbine installation.”

For his part Jesper Moeller, Siemens Gamesa chief engineer execution, said, “This is crucial for the technical readiness of next-generation offshore wind turbine installations, even under challenging wind conditions. The resulting increase in installation uptime will be accompanied by a positive effect on the operational activities in general, as well as increased on-site safety. Siemens Gamesa sees the system as a potentially new industry standard with benefits for the whole wind industry, providing more productive vessel days, while at the same time reducing (de-)mobilisation times. Hence, Siemens Gamesa will consider the availability of the new Travelling Load Stabilising System on installation vessel cranes as a significant factor in decision making when selecting and hiring appropriate installations vessels in the future.”

See a video illustating how the TLSS works.

One of the two pairs of trolleys operated by tugger winches. Image: Huisman

One of the two pairs of trolleys operated by tugger winches. Image: Huisman

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.