06 September 2021

Our annual TopLift contest is back and it’s time for you to vote for your favourite lift from our selection of ten terrific lifts featured in International Cranes and Specialized Transport magazine. To choose your winner, pick your preferred lift from the selection by completing and returning the editable form at the bottom of this page or by clicking the button above.

ENRTY 1. NIGHT FEVER

Equipment user: Nolte Autocrane

Equipment used: Liebhherr LTM 1250-6.1, three LTM 1200-5.1s and two smaller mobile cranes

Location: Hannover, Germany

Six wheeled mobile cranes, all Liebherrs, worked through the night to install a 70 metre skywalk in Germany. The cantilever connection bridge was more than 70 metres long. Trees, road signs and overhead cables for a tram prevented the entire bridge being lifted from the ground in one piece so the two bridge sections were suspended in the air for 22 hours by the four large cranes while the two smaller cranes installed 70 top and bottom steel chords to make up the latticework sides.

ENTRY 2. TANDEM TRIUMPH

Equipment user: Wagenborg Nedlift

Equipment used: Tadano ATF 400G-6 and Demag AC 500-2

Location: Netherlands

Netherlands-headquartered lifting and transport specialist Wagenborg Nedlift carried out a tandem lift of a pressure vessel using two all terrain cranes: a Demag AC 500-2 and a Tadano ATF 400G-6. The vessel, which weighed 138 tonnes and was 12.8 metres long, had to be lifted from a roll-on/roll -off pontoon and onto a self-propelled modular transporter so that it could be taken to its destination by land.

ENTRY 3. BIG CARL’S BIGGEST LIFT

Equipment user: Sarens

Equipment used: 5,000 tonne capacity SGC 250 crane

Location: Somerset, UK

Sarens’ 5,000 tonne capacity SGC 250 crane, nicknamed ‘Big Carl’, completed its heaviest lift, at Hinkley Point C nuclear power station in the UK. The crane lifted a 575 tonne load comprising the first of three prefabricated steel rings forming a reinforced cylinder around the nuclear reactor. The ring is 17 metres tall with a diameter of 47 metres and weighed 382 tonnes.

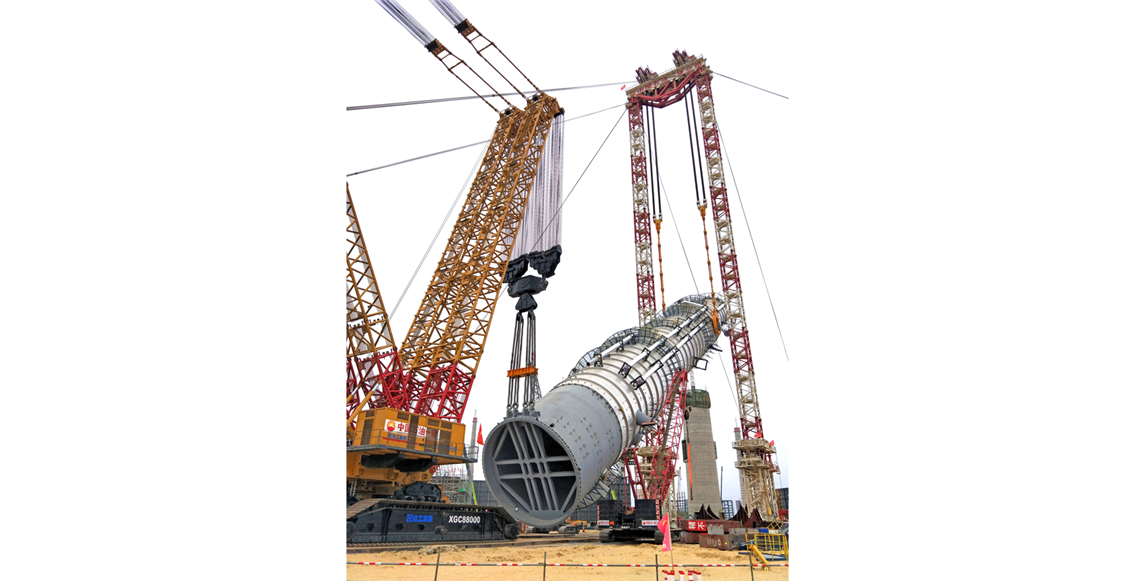

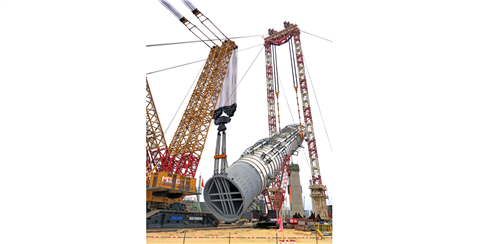

ENTRY 4. RECORD BREAKING

Equipment user: China Petroleum First Construction Corporation

Equipment used: MYQ5000 super heavy lift twin tower system

Location: Guangdong, China

Erection of a refinery vessel weighing almost 4,000 tonnes set a new record on a Chinese refinery project. China Petroleum First Construction Corporation used a 5,000 tonne capacity MYQ5000 gantry lifting system to install a 3,960 tonne raffinate tower, Asia’s heaviest single tower.

ENTRY 5. RAISING THE ROOF

Equipment user: Grefer Dach

Equipment used: Bocker AK 52 truck-mounted crane

Location: Bochum, Germany

Grefer Dach used a Bocker AK 52 truck-mounted crane to help in the renovation of the slate roof of a historic town hall in Bochum, West Germany. With a capacity of 12 tonnes and extension length of 52 metres, the crane lifted building materials from the building’s inner courtyard up and over the 35 metre high roof ridge.

ENTRY 6. PERFECT FIT

Equipment users: Orange County Ironworks and McLaren Engineering Group

Equipment used: 500 tonne capacity Liebherr LTM 1500

Location: New York City, USA

Working in New York City’s tight building space constraints, McLaren Engineering Group lifted a 130 tonne capacity Liebherr LTM 1130 wheeled mobile crane onto the roof of Tiffany & Co.’s flagship retail store using a 500 tonne capacity LTM 1500 to support the store’s renovation.

ENTRY 7. VIRTUAL VICTORY

Equipment user: Heibedrijf M. Kool

Equipment used: 70 tonne capacity Sennebogen 673E

Location: Holland

Heibedrijf M. Kool used its 70 tonne capacity Sennebogen 673E to install sheet piles for the construction of a new pumping station for general contractor Vobi. Overhead power lines restricted the working height when installing sheet piles for the construction of a new pumping station so the crane driver relied on the Sennebogen 673E’s Virtual Wall function to alert them if the telescopic boom left the predefined area and got too close.

ENTRY 8. BRIDGING BRILLIANCE

Equipment user: Anglemyer Crane Rental

Equipment used: 100 tonne Link-Belt HTC-86110 hydraulic truck crane and 250 tonne Link-Belt ATC-3275 all terrain crane

Location: California, USA

Anglemyer Crane Rental used its 100 tonne Link-Belt HTC-86110 hydraulic truck crane and 250 tonne Link-Belt ATC-3275 all terrain crane to tandem lift a 47 metre long, 27 tonne refurbished water bridge used to circulate water for the industrial production of sand.

ENTRY 9. WIND FARM WONDER

Equipment user: Huisman

Equipment used: 2,600 tonne Skyhook Crane

Location: Xiamen, China

Huisman’s Skyhook crane in China lifted its first offshore wind farm components. The slewing jib quayside crane hoisted 100 metre long foundation monopiles, each weighing 1,700 tonnes, from the deck of a cargo vessel. According to its manufacturer, the Skyhook is the largest slewing jib quayside crane in the world, capable of lifting 2,600 tonnes at a 30 metre radius. This fully electric crane can also provide regenerative electricity back to the grid.

ENTRY 10. GIRL POWER

Equipment user: GGR Group

Equipment used: URW-706 Unic mini spider crane

Location: Bedford, UK

A six tonne capacity Furukawa Unic model URW-706 spider type mini crawler crane was used for lifting operations on a refurbishment project at the 18th Century Stevington windmill in Bedford, UK. The crane was operated by two female operators, Kirsty Parkin and Olivia Rollinson, both from GGR Group. They used the crane to lift and place structural beams weighing 300 kg and also lifted the historic mill’s sail frames ready for installation.

Supporting documents

Click links below to download and view individual files.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.