Lift planning software continues to evolve

12 July 2021

With millions of configuration options, this lift planning technology is a critical part of a successful and safe lift.

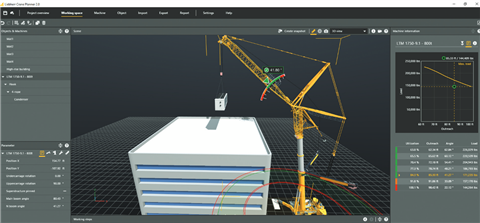

Preparation, preparation, preparation. No one understands this sentiment better than a construction crew operating heavy machinery with a larger-than-life footprint. As cranes become more sophisticated, load planning software has become even more essential for a safe and successful project. While watching a demonstration of the Liebherr Crane Planner 2.0 software over Microsoft Teams, I jokingly asked Christoph Mai, product manager, digital solutions and consulting for Liebherr-Werk Nenzing, if he ever felt like he was playing a video game.

Liebherr’s Crane Planner 2.0 offers the ability to utilize virtual reality to view a lift plan in full immersive 3D.

Liebherr’s Crane Planner 2.0 offers the ability to utilize virtual reality to view a lift plan in full immersive 3D.

However, it’s not a game and the stakes are high and very real. Lift planning software is a necessary step when planning picks. With millions of configuration options, this evolving technology is a critical part of a successful and safe lift.

“It’s a great equalizer for the crane owner to be able to deliver a lift plan that both appears, delivers and illustrates state-of-the-art planning and data,” said Pat Collins, director, product marketing, Link-Belt Cranes. “It’s not just for the people that have their own engineering firm or their own CAD. I think that is big.”

While it continues to develop, the technology is also becoming more attainable.

“It makes everybody address certain factors of the lift to develop a plan,” added Collins. “It doesn’t solve everything. Obviously, the cranes are there making lots of other lifts. But for identified lifts, be it critical lifts by whatever definition, it illustrates that there’s a plan and consideration for critical factors, rather than showing up and assuming everyone knows everything, which tends to be one of the common factors in an accident.”

Innovations and integration

A1A Software has seen that as customers increasingly need lift planning tools in the field, lift planning is becoming more app driven.

“Mobile device applications enable work to get done more efficiently, especially for sales and estimating tasks,” said Tawnia Weiss, president, A1A Software. Engineers and lift planners are still utilizing lift planning tools in desktop mode back at the office, however, app-friendly lift planning is sufficient for preliminary plans and estimating.”

Jim Jatho, product manager crawler cranes for Liebherr USA, mentioned that for larger, more complex projects, there has been a strong emphasis on

3D planning and integration of real-world data, such as Google Maps, BIM data and field surveys/laser scanning.

“As an example, most recent football stadium projects would have been impossible to accomplish without precise 3D modeling of both cranes and the structures themselves to prevent conflicts,” said Jatho.

Market offerings

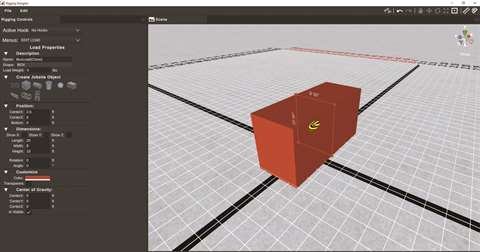

A1A Software will soon be releasing a 3D rigging designer app, which enables robust rigging planning to be done independently of 3D Lift Plan. The app will work on any Android tablet or Apple iPad, as well as on PCs or Macs. Standard slings, hardware and spreader bars are available in the app, and custom rigging can be created in the app. All rigging objects can be saved to a library and used later in conjunction with 3D Lift Plan.

A1A Software will soon be releasing a 3D rigging designer app, which enables robust rigging planning to be done independently of 3D Lift Plan.

A1A Software will soon be releasing a 3D rigging designer app, which enables robust rigging planning to be done independently of 3D Lift Plan.

In addition, an app version of Sketchpad, the web tool introduced in 2019, is expected to be released by the end of the year. Sketch pad allows estimators, project managers or others involved in initial job bidding or lift planning to draw on screen using their finger. One of the new features in the app version will be location services. This enables exact latitude and longitude coordinates based on the location of the crane’s center pin and the load’s location, further maximizing convenience of gathering initial information for a job estimate. In 2022, A1A advises customers to look for a full 3D Lift Plan app.

Liebherr still utilizes the LICCON work planner software for all cranes 350 metric tons and higher. The newest offering is Crane Planner 2.0, which is a full 3D lift planning program developed exclusively by Liebherr. It is a standalone Windows application, so changes happen instantly, whereas online solutions require a web page to refresh. It is also a dynamic “click and drag” interface where adjusting any aspect of a crane is as simple as clicking the right area and moving the crane with the mouse. There is a robust report designer function that allows the user to create detailed reports, all without the use of expensive CAD software. All data comes direct from Liebherr, eliminating the problem of third party software developers using erroneous crane data.

Additionally, Liebherr recently launched a new tool, Crane Finder. Available at MyLiebherr.com, Crane Finder takes simple input parameters and produces a list of all Liebherr cranes and combinations that are capable of making the lift. It is an extremely easy tool to initiate the process of crane selection, which can then be fine-tuned by the user.

Link-Belt has updated its lift planning menu with the addition of its latest products into the platform. The HT 65 and the TCC550 are being introduced into the menu while the company has also begun the process of loading the new products that will be unveiled at Crane Fest. Once they are released, Link-Belt will be able to “flip the switch.”

“We’re also going to expand the luffer ground bearing program on our site, hopefully to very soon expand ground bearing on crawler cranes and luffers to an even broader application than what we have,” added Collins. “It’s a segment of lift planning. The ground bearing factor is becoming a more visible factor and visible concern for more crane users than in the past.”

JJ Curran deployed its Grove all-terrain cranes to hoist a 116.5- ton gas “scrubber” from a barge docked on the Detroit River to the dock on Zug Island. This complex lift required a detailed lift plan.

JJ Curran deployed its Grove all-terrain cranes to hoist a 116.5- ton gas “scrubber” from a barge docked on the Detroit River to the dock on Zug Island. This complex lift required a detailed lift plan.

Manitowoc also offers a range of lift planning tools for its customers worldwide. More specifically, CRANEbee, in partnership with CRANIMAX is a tool for Grove GMK all-terrain crane and Manitowoc crawler crane job planning that enables users to visualize cranes in a construction site environment using realistic and interactive 3D models. Based on the findings, the best crane for a job is determined, reducing transport and setup costs, the company said. The feasibility of a project is guaranteed by professional project drafts calculated with precise ground bearing pressures.

Next steps

Construction customers are demanding more information from the crane providers, and expecting ever-more detailed plans, reports and information about the crane and rigging,” said Weiss. “App-based tools will help crane providers be competitive and satisfy customers’ and potential customers’ requests for comprehensive lift planning documentation.”

Liebherr’s Crane Planner 2.0 already offers the ability to utilize VR to view a lift plan in full immersive 3D.

“I think the next step will be augmented reality, where a lift plan can be created and then viewed in full scale on a jobsite with AR goggles,” concluded Litho. “I imagine a day when lift plans are no longer submitted for review on paper, but rather a team equipped with AR goggles views the lift happen virtually in real time on an active jobsite. Beyond that, I think the future will bring us a more advanced version of the Crane Finder tool, where a user enters in information about a lift and an AI network handles all aspects of a lift plan, from crane selection to final report creation.”

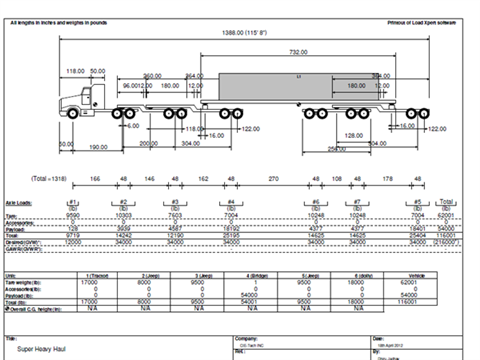

The company’s software offers axle load calculation for heavy haul vehicles (tractor, jeep, drop decks, bridge, bridge dolly & booster), super heavy haul vehicles (tractor, jeep, reverse jeep, spreader bridge, bridge dollies, and pusher trucker), and regular vehicles (straight truck, pup, full trailer, semi-, B-trains and A-, & C- trains). Different units can be combined to create a combination vehicle for hauling.

STAY CONNECTED

Receive the information you need when you need it through our world-leading magazines, newsletters and daily briefings.